Fracturing: Advanced Chemical Solutions for Enhanced Oil and Gas Production

Fracturing, often called hydraulic fracturing or “fracking,” is a technique used in the oil and gas industry to extract underground resources such as oil, natural gas, and geothermal energy. The process involves injecting a high-pressure fluid mixture of water, sand, and various chemicals into a rock formation. This creates fractures in the rock, allowing the trapped resources to flow more freely to the wellbore for extraction commonly referred to as hydraulic fracturing or fracking, is a method used primarily in the oil and gas industry to extract underground resources such as oil, natural gas, and geothermal energy. This technique has revolutionized the energy sector by enabling access to vast reserves of hydrocarbons that were previously unreachable or uneconomical to produce.

- Gelling Agents – Guar Gum Polymers

- Buffers

- Crosslinkers

- Friction Reducers

- Clay Stabilizers

- Biocides

- Breakers

- Foaming Agents

- Surfactants

-

Gelling Agents – Guar Gum Polymers

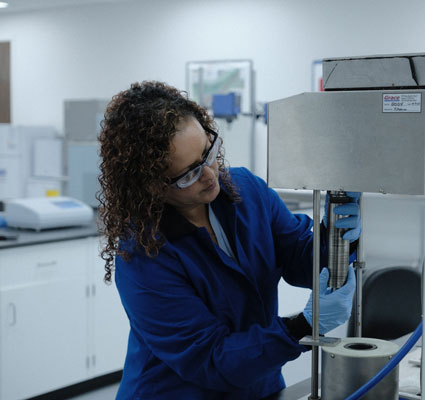

Gelling Agents – Guar Gum PolymersSunita provides GUAR GUM, a natural galactomannan polysaccharide derived from the endosperm of the Cyamopsis tetragonolobus legume, predominantly found in arid and semiarid regions of India. Our fast-hydrating Guar Gum is a staple in various oil field applications, especially in fracturing operations.

Acting as both a friction reducer and a gelling agent, Guar Gum facilitates fluid flow into fractures. When crosslinked with metal ion-based agents, it achieves high viscosity, efficiently transporting proppant deep into fractures. With the ability to adjust crosslink viscosity, our Guar Gum allows control over fracture dimensions and growth, ensuring optimal performance in every application. Sunita provides various grades of Guar and derivatized Guar, such as CMHPG (carboxymethyl hydroxypropyl guar), which can be delivered in dry and slurry form.

-

Buffers

BuffersSunita provides a diverse range of buffering agents tailored to meet the specific requirements of fracturing applications. Our buffers feature sodium and potassium cations paired with hydroxide, or carbonate anions. Available at various concentrations, our buffering agents are designed to perform reliably across a wide temperature range. For lower temperature settings, we offer a potassium hydroxide solution optimized for crosslinking guar. The buffer loading can be adjusted to achieve desired fluid characteristics. At moderate to higher temperatures, our specialized buffer combines potassium hydroxide and potassium carbonate in an optimized ratio, ensuring exceptional crosslinked viscosity and stability. Our buffers are customized, allowing for precise adjustment of pH levels to maintain fluid integrity and performance.

-

Crosslinkers

CrosslinkersCrosslinkers play a vital role in enhancing the viscosity of gelled fracturing fluids in oil field applications. Different types of guar gum and its derivatives, such as Hydroxypropyl Guar (HPG), Carboxymethyl Guar (CMG), and Carboxymethyl Hydroxypropyl Guar (CMHPG), can undergo crosslinking with various agents, including borate, zirconate, aluminum, or titanium-based crosslinkers. While borate crosslinkers are commonly paired with Guar gum, zirconate crosslinkers are preferred for derivatized guars due to their cost-effectiveness and technical efficiency. This selection process ensures optimal performance and cost efficiency in fracturing operations.

Sunita provides a comprehensive range of crosslinkers tailored for fracturing applications. Our offerings include borate and zirconate crosslinkers, as well as a unique dual crosslinker that combines both in a single product. We offer various borate products, including surface and delayed crosslinkers designed for both low and high-temperature environments. The delayed borate crosslinker is suspended in a BTEX-free mineral oil for ease of use. Additionally, we offer a variation that combines buffer with a surface crosslinker, streamlining costs and reducing the number of products needed on-site. Our zirconium crosslinkers cater to both high and low pH systems, ensuring versatility and efficiency in fracturing operations.

-

Friction Reducers

Friction ReducersFriction reducers play a critical role in fracturing applications by reducing the hydraulic horsepower required for fluid injection. Among the most commonly used polymers is PHPA (Partially Hydrolyzed Polyacrylamide), which is typically a copolymer of acrylamide and another compound like acrylic acid or a sodium salt of acrylic acid. These polyacrylamides typically boast extremely high molecular weights and carry anionic charges. In certain scenarios involving higher density brines or produced water, cationic polymers might be employed.

At Sunita, we offer a comprehensive range of products tailored for treating fluids, accommodating everything from fresh water to high-density brines and produced waters. Our friction reducer products are available in various forms including emulsions, slurries, or dry products, ensuring versatility and effectiveness across diverse operational requirements.

HYSLIC Friction ReducersSunita introduces a proprietary and patented series of Friction Reducers meticulously crafted to address specific field and treatment fluid requirements. Available as either a dry product or a slurry, our HYSLIC Friction Reducer stands out for its exceptional effectiveness in challenging conditions, including environments with high concentrations of iron, high-density produced waters containing various difficult ions, and situations necessitating crosslinked fluid. HYSLIC can be crosslinked, serving dual roles as both a friction reducer and a gelling agent, thereby eliminating the need for additional products on-site. For further information on this innovative series of products, please feel free to inquire for more details.

-

Clay Stabilizers

Clay StabilizersClay stabilizers play a crucial role in reducing clay swelling and migration during fracturing operations. As the fracturing process can cause clay particles to disintegrate, they may swell when exposed to water ions, leading to pore blockage. Clay stabilizers operate through ion exchange, replacing the native clay cations like sodium with stabilizing cations. Potassium chloride is commonly used at high concentrations (2-4%) but requires on-site preparation as a solution. Choline chloride (65-75%) presents an appealing alternative due to its low cost and easy handling, serving as an effective temporary stabilizer. Quaternary amines, such as Tetramethyl Ammonium Chloride (TMAC), are widely used for clay stabilization. For longer-term stabilization, polymeric quaternary amines are preferred. Sunita offers a comprehensive range of Clay Stabilization products, including all these types. For further details, please reach out to a Sales representative.

-

Biocides

BiocidesBiocides are essential in oilfield operations to safeguard stimulation or drilling fluids from bacterial contamination and to prevent bacterial invasion into the reservoir. Bacteria can degrade the polymers used in stimulation fluids, reducing their viscosity and friction-reducing abilities. Contamination of reservoirs by bacteria introduced through stimulation fluids can lead to souring. Glutaraldehyde is effective against sulfate-reducing bacteria and provides long-term protection, while quaternary ammonium-based biocides offer rapid elimination but have a shorter lifespan. Sunita provides reliable Biocides for drilling and stimulation, including Glutaraldehyde, DDAC (didecyl dimethyl ammonium chloride), and blends of Glutaraldehyde with quaternary ammonium-based compounds.

-

Breakers

BreakersOxidizing Breakers

Sunita offers a diverse range of breaker agents designed to effectively degrade both gelling agents and friction reducers. Through the thermal degradation of oxidizing breakers, free radicals are generated, which target the polymer backbone, cleaving it into smaller segments and thereby diminishing viscosity. This process enables the fracturing fluid’s viscosity to be lowered to levels comparable to water, facilitating a more efficient fluid return to the surface. Oxidizing breakers are available in both liquid and solid forms. Common examples include sodium and ammonium persulfate, which act as non-delayed breakers, initiating viscosity reduction at temperatures exceeding 120°F. However, an activator is necessary for lower temperature applications.

Encapsulated Breakers

Encapsulated breakers are engineered to gradually release an oxidizing agent, serving as an effective breaker in guar and guar derivative-based fracturing fluids operating at temperatures below 300˚F. This innovative solution enables the use of higher concentrations of breaker without compromising fluid viscosity during proppant placement. Consequently, operators gain flexibility in controlling the timing of fluid break or have the option to employ increased breaker concentrations for enhanced performance. Increased breaker concentrations often improve proppant pack clean-up, thereby bolstering fracture conductivity. Sunita offers encapsulated Ammonium Persulfate tailored for delayed applications at moderate temperatures, as well as encapsulated Sodium Bromate optimized for high-temperature environments.

Enzyme Breakers

Sunita provides enzyme breakers meticulously crafted for breaking down Guar polymer. These specialized enzymes efficiently decrease fluid viscosity, even in temperatures reaching up to 250°F. Notably, enzymes remain active throughout the breaking process, persisting over time. This continuous action enables the gradual reduction of polymer segments into shorter, cleaner fragments, resulting in a more refined broken fluid.

-

Foaming Agents

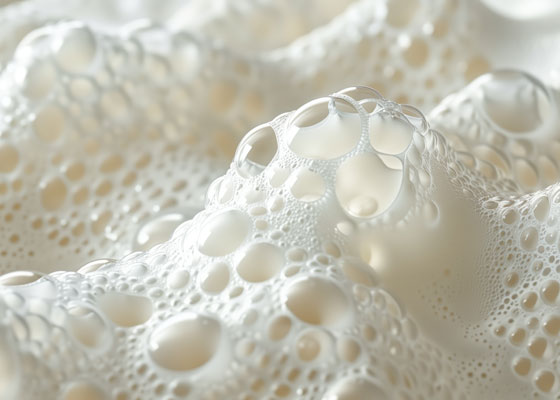

Foaming AgentsFoaming agents represent a crucial component in oilwell fracturing applications, serving to optimize fluid performance and enhance well productivity. These specialized additives are adept at generating stable foam, consisting of gas bubbles dispersed within a liquid phase. By entraining gas, typically nitrogen or carbon dioxide, into the fracturing fluid, foaming agents significantly reduce fluid density, effectively mitigating the risk of formation damage and improving the transport of proppants deep into the fractures. Moreover, foam exhibits superior mobility, allowing it to reach remote areas within the reservoir with ease. Foaming agents play a vital role in controlling fluid loss and maintaining wellbore stability, particularly in challenging environments characterized by high temperatures and pressures.

Sunita offers a wide range of foaming agents tailored for oilwell fracturing needs, ensuring top-notch performance and efficiency. Our selection includes foaming agents with different charge characteristics like anionic, cationic, amphoteric, and zwitterionic, catering to various operational requirements.

-

Surfactants

SurfactantsSurface-active agents, commonly referred to as surfactants, are chemical compounds that operate at the interface of immiscible phases. Within fracturing applications, surfactants play a pivotal role in mediating interactions between oil and water interfaces, whether within the stimulation fluid itself or between the stimulation fluid, the formation, and/or the formation fluids. Optimizing the surface tension, contact angle, and interfacial tension of fluids improves the performance of stimulation fluids in several areas. These surfactants function as wetting agents, flowback aids, fluid recovery agents, and dispersing agents, among other crucial roles.

Surface tension reducers are meticulously crafted surfactants designed to significantly diminish surface tension in a wide array of applications, including different types of acids, water-based fracturing fluids, and brines. Sunita offers engineered surfactants with remarkably low surface tensions compared to many alternatives on the market. Leveraging innovative processing techniques, these products yield exceptionally effective surfactants that, even at low concentrations, deliver substantial reductions in surface tension.

Sunita offers a comprehensive range of products designed to enhance the performance, reliability, and efficiency of operations in the oil and gas industry. Our specialized hydrocolloid-based products cater to a variety of applications, including fracturing, cementing, acidizing, and more, providing tailored solutions for the most demanding environments.

At Sunita USA , we offer a comprehensive suite of specialized services designed to meet the diverse needs of our clients across various industries. Our expertise and advanced capabilities ensure that we deliver tailored solutions with exceptional quality and efficiency.