Industry Leader In Oilfield Innovation & Technology

Founded in 2013, Sunita Hydrocolloids Inc., USA (SHI) is a subsidiary of Sunita Hydrocolloids Private Limited, India established in 1982. SHI USA focuses on innovative oil field chemical technology, providing a variety of quality stimulation chemicals such as guar-based gelling agents, cross linkers, clay stabilizers, defoamers, non-emulsifiers, and breakers to the North and South American markets.

40-year industry leader based in India, Sunita Hydrocolloids Inc produces 50,000 metric tons annually using patented Hislick technology thereby, boosting output by 400%. Specializing in oil and gas products, SHI offers toll blending and custom formulations while Sunita Logistics in Texas ensures efficient U.S. service with top quality, pricing, and delivery.

Guar gum polymers act as gelling agents in the hydraulic fracturing process, essentially thickening the water-based fracturing fluid, allowing it to effectively carry and suspend proppant particles deep into the newly created fractures within the rock formation. Due to its high viscosity and ability to form a stable gel-like consistency even at low concentrations, guar gum polymers maximize the production potential of wells by keeping the fractures open after the pressure is released.

Buffers are used in the fracturing process to control the pH level of the fracturing fluid. This maintains optimal viscosity and performance of the fluid during the creation of fractures in the rock formation. Crucial for effective proppant placement and preventing unwanted chemical reactions within the wellbore, buffers ultimately maximize the efficiency of the fracturing operation.

Crosslinkers are chemical additives used in hydraulic fracturing fluids to create a strong and stable gel by linking polymer chains together. This allows the fluid to maintain a high viscosity and effectively carry proppant particles deep into the rock formation to create and hold open new fractures.

Friction reducers are chemical additives used in hydraulic fracturing (fracking) during well completion to reduce friction within the wellbore. This allows for significantly efficient pumping of the fracturing fluid at high pressures by lowering the resistance against the wellbore walls. Ultimately, this maximizes the effectiveness of the fracturing process.

Clay stabilizers are chemical additives used during hydraulic fracturing to prevent clay particles within the reservoir rock from swelling and migrating clays can damage the formation and decrease the production of hydrocarbons. Clay stabilizers are a necessary precaution against reduced production in some formations.. Basically, they help ensure the fracturing fluid reaches the desired target area without being hindered by swollen clay particles that could block the flow of oil and gas.

Biocides are added to fracturing fluids during the well-completion process to prevent the growth of bacteria within the newly created fractures. These bacteria could otherwise lead to issues like corrosion, souring of the reservoir, and reduced production by blocking the flow of oil and gas with biofilm buildup.

Breakers are chemical additives used in fracturing fluids that help reduce viscosity after the fracture is created. This allows the proppant (small particles used to keep the fracture open) to settle effectively within the fracture for efficient flowback of the fracturing fluid. This, in turn, maximizes oil and gas recovery from the well.

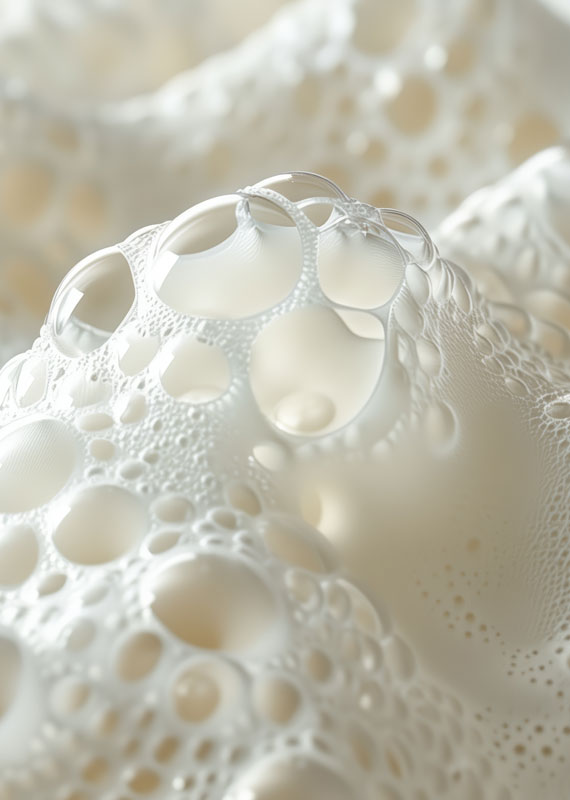

Foaming agents are used during the well completion process, particularly in hydraulic fracturing (“fracking”), to create a foam that increases the viscosity of the fracturing fluid. This allows for better proppant suspension and placement within the created fractures.

Surfactants are added to fracturing fluids during well completion. Surfactants decrease the likelihood of negative interactions between the fracturing fluid, the formation, and the hydrocarbons and thereby help to improve production. This allows for better penetration and wider fracture propagation, ultimately leading to increased oil and gas production.