Struggling with slow flowback or formation damage? Every fracturing operation faces a critical challenge: efficiently breaking down viscous gels after stimulation to restore optimal well productivity as slow or incomplete degradation leads to costly formation damage, delayed production and lost revenue.

Sunita Hydrocolloids’ high-performance fracturing gel breakers solve this problem with precision-engineered chemistry that ensures rapid viscosity reduction and minimizing flowback time. Our ultra low residue formulation protects reservoir permeability and custom activation is designed for each well’s temperature, pH and fluid system.

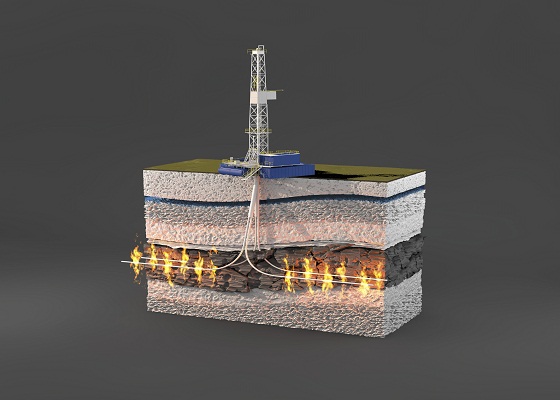

Hydraulic fracturing fluids rely on polymers like guar gum or Hydroxypropyl Guar (HPG) to carry proppants deep into fractures. Once the job is done, these thick gels must break into thin, flowable fluids to prevent blockages in proppant packs, restore natural permeability for hydrocarbon flow and reduce cleanup costs by accelerating flowback.

Without effective breakers, residual gel can clog fractures, reducing well productivity and increasing operational costs. The right breaker fluid ensures a complete transition from viscous gel to a free flowing fluid. Breakers are used in linear gels, cross linked gels, high viscosity friction reducers (HVFRs) and more. They help reduce their polymer mass, maximizing efficiency and protecting reservoir integrity.

Hydraulic fracturing relies on breakers to degrade the thick gels used during stimulation, restoring fluid flow and preventing blockages. Different types of breakers work in distinct ways to achieve this, ensuring efficient cleanup and optimal production.

Enzyme breakers have the advantage of continuing to work. They are not immediately consumed like oxidative breakers. They simply cleave the polymer bond closest and look for another polymer bond to cleave.

Each type plays a critical role in optimizing well productivity, ensuring a complete and efficient cleanup while protecting long-term reservoir performance.

Sunita’s breakers rapidly degrade residual gelled fluids in the wellbore and fracture network, ensuring faster, more efficient cleanup and unrestricted hydrocarbon flow.

By breaking down polymer-based gels, our breakers enhance reservoir connectivity, improving fluid mobility for higher production rates and maximized asset ROI.

Engineered to preserve reservoir permeability, our low-residue breakers prevent pore blockages, extending well life and maintaining long-term productivity.

Compatible with all major fracturing fluids (guar, HPG, synthetic polymers) and additives, our breakers adapt to any reservoir condition or operational need.

Don’t let inefficient breaking delay your production. Sunita Hydrocolloids’ breakers are proven, customizable and backed by years of oilfield expertise. Contact us for tailored solutions!

SUNCOL is a versatile product. It dissolves in both hot and cold water, exhibits strong hydrogen bonding, and has excellent thickening and stabilizing properties, making it an exceptional stabilizer. .