Acidizing is a technique employed in the oilfield to enhance well productivity by stimulating reservoir formations. Various acidizing products are utilized in this process to optimize performance and ensure the longevity of the wellbore. Gelling agents are commonly employed to thicken the acid solution, enhancing its viscosity and ensuring deeper penetration into the formation. Corrosion inhibitors play a vital role in mitigating metal corrosion within the wellbore, safeguarding equipment and infrastructure from degradation. Corrosion intensifiers are utilized to enhance the corrosion inhibitors’ effective temperature range, thereby increasing their effectiveness in protecting downhole hardware.

Non-emulsifiers are essential additives utilized to prevent the formation of undesirable emulsions during acidizing treatments, ensuring efficient fluid recovery and well cleanup. Iron control agents are deployed to mitigate the adverse effects of iron precipitation, which can impede fluid flow and hinder well performance. Lastly, paraffin and asphaltene solvents are utilized to dissolve and remove organic deposits that may impede production, ensuring uninterrupted flow and maximizing well productivity. Overall, the judicious selection and application of these acidizing products are instrumental in optimizing well performance and maximizing hydrocarbon recovery in oilfield operations.

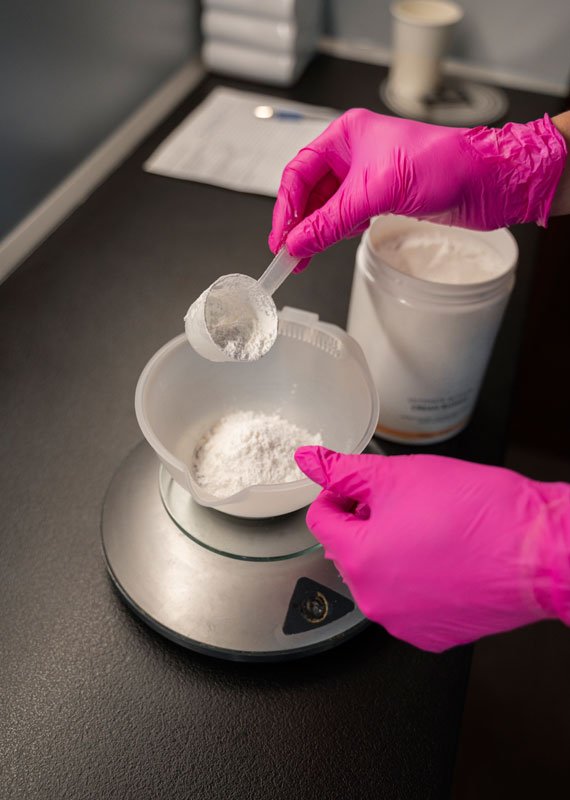

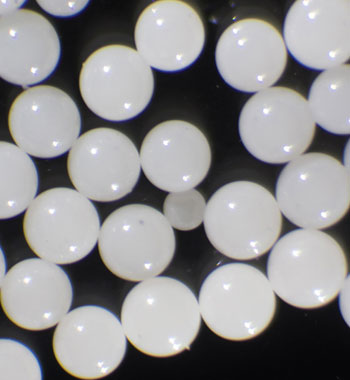

SUNCOL is a versatile product. It dissolves in both hot and cold water, exhibits strong hydrogen bonding, and has excellent thickening and stabilizing properties, making it an exceptional stabilizer. .