Key Benefits of Custom Blending in the Oil & Gas Industry

As the U.S. oil and gas sector faces rising complexity, tighter regulations and shifting production demands, precision chemical blending has become a critical performance lever. Off-the-shelf solutions often fall short in unconventional reservoirs, enhanced recovery and hydraulic fracturing. Custom blending offers a smarter path, delivering targeted surfactants and additives that match field conditions, reduce waste and improve operational efficiency.

In addition, custom blending solutions provide significant convenience to operators by improving reliability and reducing the risk of errors. This blog outlines how tailored formulations drive measurable gains across upstream and midstream operations. By leveraging custom blending, oil & gas operators can unlock their own benefits such as maximizing value, efficiency and product quality, compared to generic solutions.

Sunita Hydrocolloids supports this shift with advanced blending capabilities focused on consistency, reliability and field-tested results. Our commitment to quality makes us a trusted partner in oilfield chemical innovation.

What Are Custom Blending Solutions?

Custom blending is the process of creating precision chemical mixtures designed for field performance. It involves selecting and combining specific components to achieve the desired results. In oil and gas, this means matching the exact needs of drilling, stimulation and production environments. Different custom blending formats include:

- Dry with dry blending: Combining powders like polymers or proppant enhancers for hydraulic fracturing

- Liquid with liquid blending: Mixing surfactants, solvents or corrosion inhibitors for fluid systems

- Dry into liquid blending: Creating slurries or suspensions for easier dosing and transport

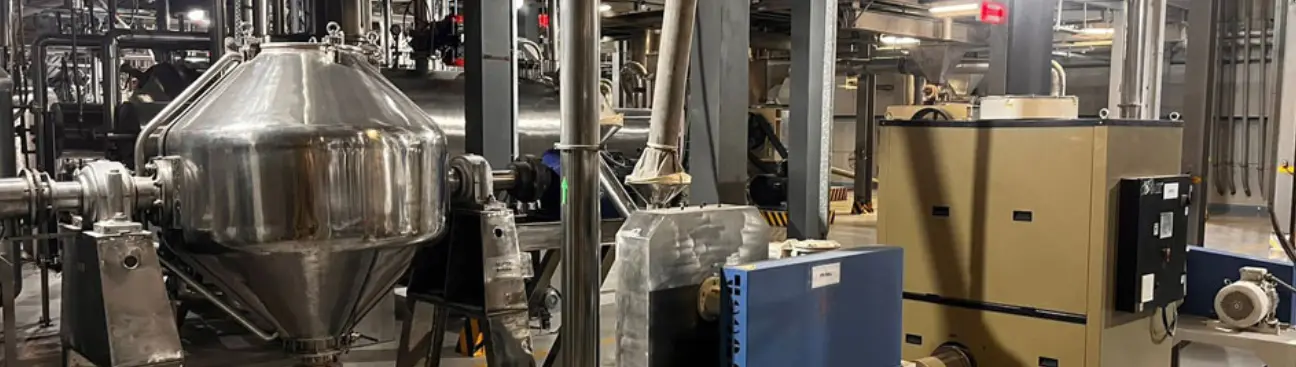

These different processes are tailored to specific operational needs. Custom blending requires careful selection and optimization of components to meet technical specifications and cost objectives. These blends are produced using purpose-built equipment that ensures dosing accuracy, batch consistency and repeatable quality.

Whether it’s surfactants for shale plays or additives for enhanced recovery, Sunita’s custom blends are engineered for reliability and performance. That’s how operators reduce waste, improve uptime and stay ahead of field variability. We have purpose built equipment to provide chemical toll blending in oil and gas industry and ensure consistent quality.

As a toll blender, Sunita Hydrocolloids can handle the entire production process for clients, from raw materials to packaging. Our processes are designed to produce high-quality results and reliable blended products, ensuring consistency and superior output for every application.

Key Benefits of Custom Blending for Oil & Gas Companies

Here is how custom blending is reshaping the way oil and gas companies manage chemical performance, cost control and field reliability.

A. Tailor-Made Formulations for Your Process

Custom blending gives operators control over key chemical properties like viscosity, particle size and surfactant behavior. This precision helps optimize performance across drilling, stimulation and production. Whether it’s improving wellbore stability, enhancing phase separation or deploying friction reducers for slickwater systems, the blend matches the job.

Oilfield operators and service companies are shifting toward engineered blends to meet rising demands for reliability and efficiency. The North American oilfield specialty chemicals market is expanding rapidly with purpose-built formulations for enhanced recovery and compliance.

B. Cost Savings and Just-in-Time Manufacturing

Custom blending cuts costs across the board. There’s no need to invest in blending infrastructure, bulk storage or excess inventory. By outsourcing to a specialist like Sunita Hydrocolloids, operators save on:

- Raw material sourcing

- Blending and packaging operations

- On-site handling and waste management

Outsourcing blending also streamlines the production process, supporting a diverse product line by allowing manufacturers to efficiently manage multiple formulations and adapt to changing market demands.

This lean approach reduces both capital and operating expenses. According to Royal Chemical, outsourcing blending can deliver measurable savings while improving turnaround times and flexibility. Sunita’s just-in-time manufacturing model ensures fresh product, reduced spoilage and better alignment with field schedules.

C. Consistency, Quality Control and Regulatory Compliance

Every batch counts. Custom blending ensures repeatable quality through precision dosing, traceable documentation and compliance with API and ASTM, and ISO 9001 standards. Each blend is carefully tested to ensure it meets the final specification required for oilfield applications. Sunita Hydrocolloids uses advanced blending tanks with agitation and temperature control to maintain product integrity.

Rigorous QA/QC protocols verify that each blend meets oilfield specs for surfactants, corrosion inhibitors and other additives. Consistency and compliance are top priorities for operators managing complex fluid systems. These quality controls ensure reliable finished products. With Sunita, reliability is built into every batch.

D. Sustainability and Environmental Responsibility

Custom blends reduce waste by delivering only what’s needed which translates to fewer unused chemicals, lower emissions and better control over environmental impact. Sunita Hydrocolloids incorporates eco-conscious ingredients and packaging practices that support cleaner operations.

By aligning with safety and environmental standards, operators meet regulatory requirements while improving field sustainability. Precision blending isn’t just smart but responsible and it’s helping oil and gas companies meet the future head on.

How Sunita Hydrocolloids Delivers Custom Blending Excellence

Sunita Hydrocolloids offers precision blending services across dry-dry, liquid-liquid and slurry formats to meet the exact needs of oilfield operations. Custom blending is available at our Houston-based facility and our Midland-based facility. Experienced technical staff work directly with operators to match blend specs to field conditions, whether it’s surfactants for hydraulic fracturing or additives for enhanced oil recovery.

We support full service delivery with integrated logistics, flexible packaging options and rigorous QA protocols. Every blend is backed by lab validation and traceable documentation. From formulation to final shipment, Sunita Hydrocolloids delivers reliability, speed and field-ready performance. This is how we help oil and gas companies stay efficient, compliant, and competitive.

How to Choose the Right Blending Partner

When selecting a custom blending partner, oil and gas companies need more than just a supplier; they need a proven collaborator with deep industry experience and technical strength. The right provider should offer a full range of blend formats including dry-dry, liquid-liquid and slurry systems, backed by purpose-built equipment and skilled staff.

Facility capacity, batch consistency and QA/QC protocols aligned with API and ISO standards are non-negotiable. Regulatory compliance and environmental safety must be built into every process. Packaging flexibility and integrated logistics also play a key role in keeping operations efficient.

Sunita Hydrocolloids stands out with decades of oilfield expertise, advanced blending infrastructure, and a customer-first approach that delivers reliable, high-performance chemical blends across the U.S. oil and gas sector.

Achieve More With Tailored Blending

Custom blending gives oil and gas operators a smarter way to manage field variability, reduce costs, and improve chemical performance. It’s not just about mixing ingredients; it’s about engineering reliability into every stage of production. From surfactants for hydraulic fracturing to additives for enhanced recovery, precision matters.

Sunita Hydrocolloids delivers that precision with proven expertise, advanced equipment, and field-tested results. Ready to improve your chemical strategy? Explore Sunita’s custom blending services or connect with our team to get started.